Anodes & Zincs

Anodes & zincs for hull, shaft, prop & rudder & engine.

222 products

Showing 169 - 192 of 222 products

Anodes & zincs for hull, shaft, prop & rudder & engine.

Marine Anodes and Zincs

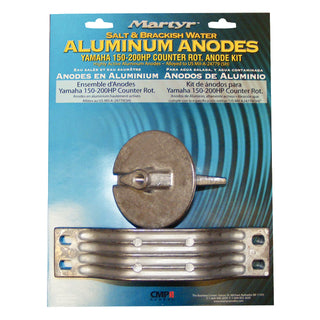

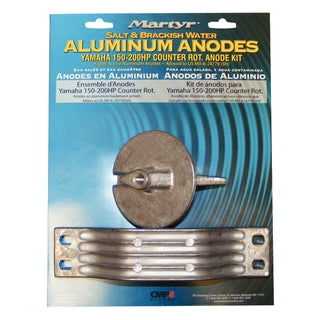

Marine Anodes and Zincs are necessary for preventing galvanic metal corrosion in boat drive systems. We supply anodes for outdrives, sterndrives, propeller shaft and propellers by popular brands like Canada Metals, Martyr Anodes and Aqua-Pacific.

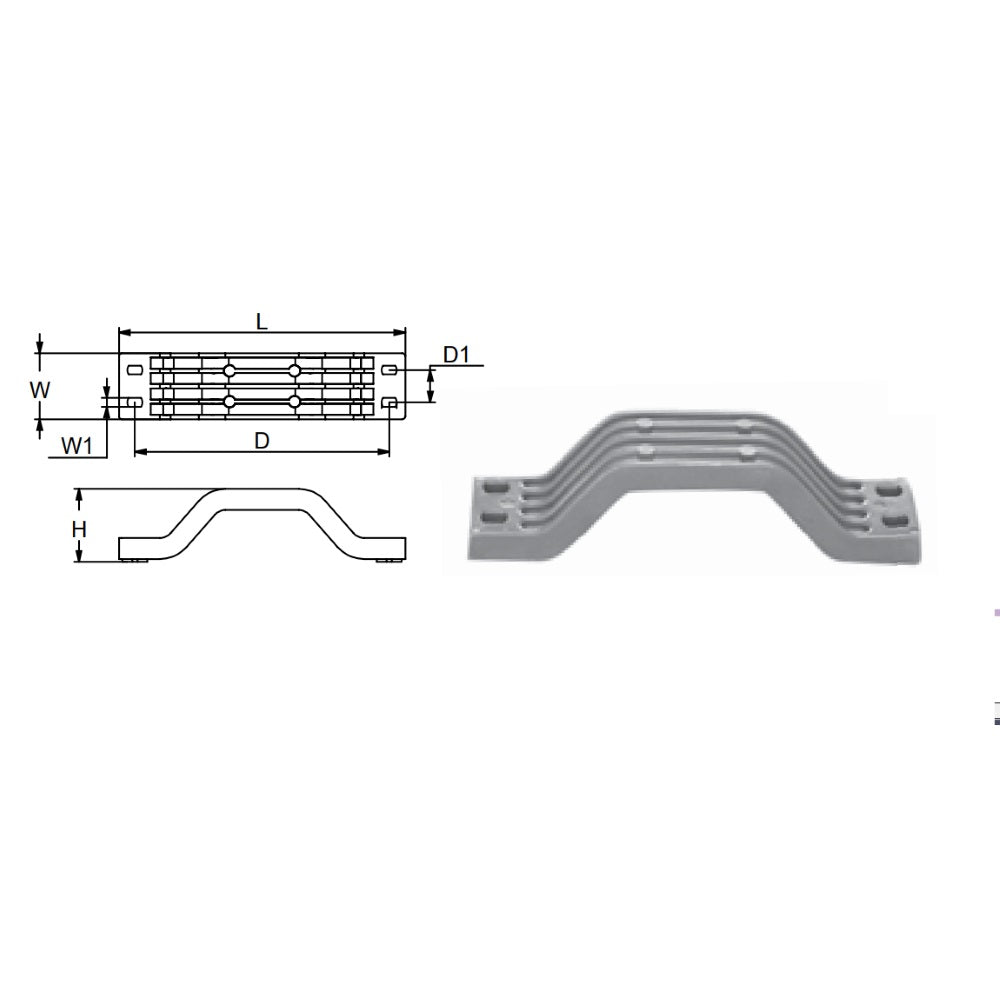

Hull Anodes

Hull Anodes are used when you have underwater fittings bonded together electrically. The hull anode depletes instead of underwater metal fittings. These anodes must be carefully monitored to protect the propeller, through-hulls or the entire hull of metal boats.

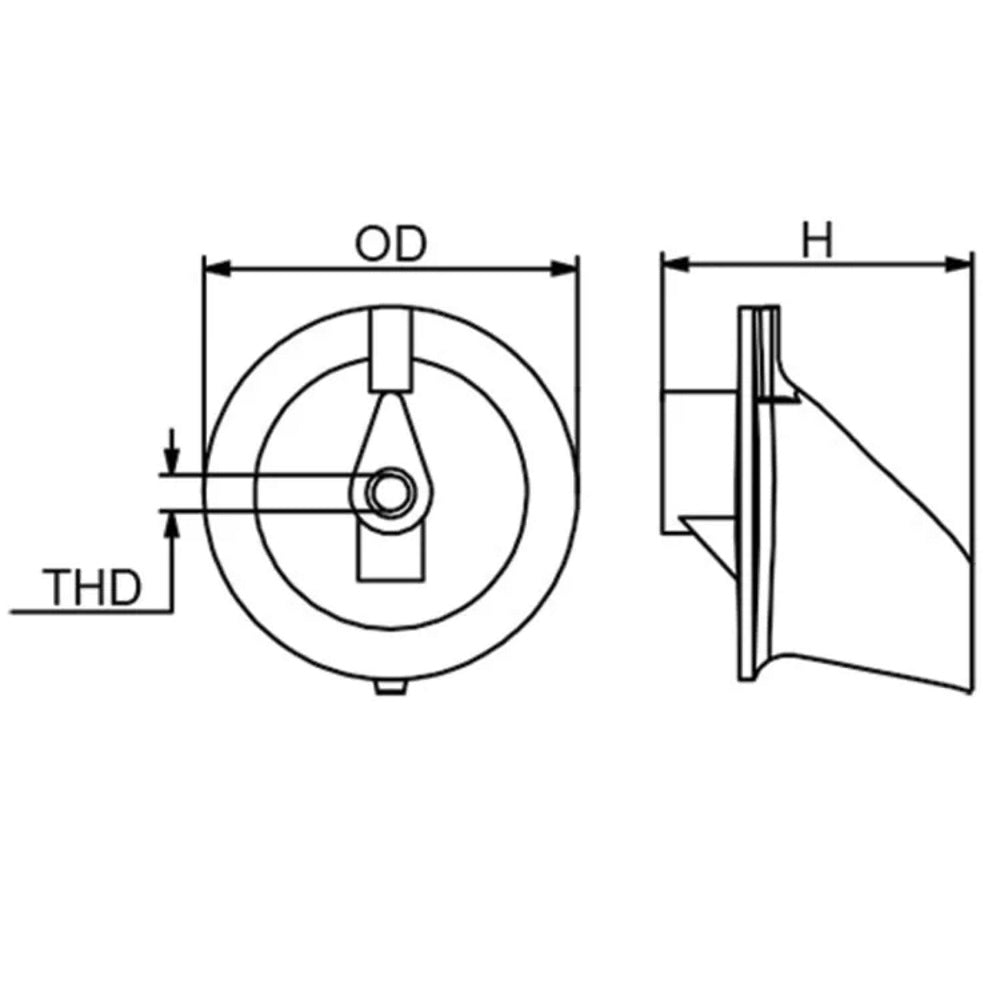

Shaft and Prop Anodes

Shaft zincs or anodes are typically fashioned in two pieces and bolted together around the propeller shaft. Propeller zincs may be a ring zinc or a zinc prop nut. Metal rudders, struts and fins are easily protected with zinc anode disks bolted through them.

What is Galvanic Corrosion and Why You Need Anodes?

Sacrificial Zincs or Anodes are used anytime you have different metals that are physically or electrically connected and immersed in water. These submerged metals will cause some amount of electrical current to flow between them. The electrons that make up that current flow are supplied by the loss of one of the metals. Metal is lost in the form of metal ions - directly into the water! Temperature and salinity (how salty the water is) also factor into how rapidly the metal is corroded. This is called galvanic or dissimilar metal corrosion and if left unchecked, it can quickly destroy underwater metals.

Common metals subject to galvanic corrosion are bronze or aluminum propellers on a stainless steel shaft; but rudders, rudder fittings, metal struts, outboards, stern drives as well as heat exchangers and through-hull fittings are also at risk. The way to counteract galvanic corrosion is to add a third metal into the circuit, one that gives up its electrons easier than the metals you want to preserve. This piece of metal is called a sacrificial anode, and most often it is zinc. In fact, most boaters refer to sacrificial anodes simply as zincs.