Most boaters make a fatal mistake: they treat their bilge pump like a standalone accessory. They buy a pump, wire it up, and assume they are safe.

They are wrong. A bilge pump is only as good as the weakest link in its plumbing. A 2000 GPH (Gallons Per Hour) pump pushing water through a corrugated, kinked hose might only deliver 800 GPH. In an emergency, that math does not work in your favor.

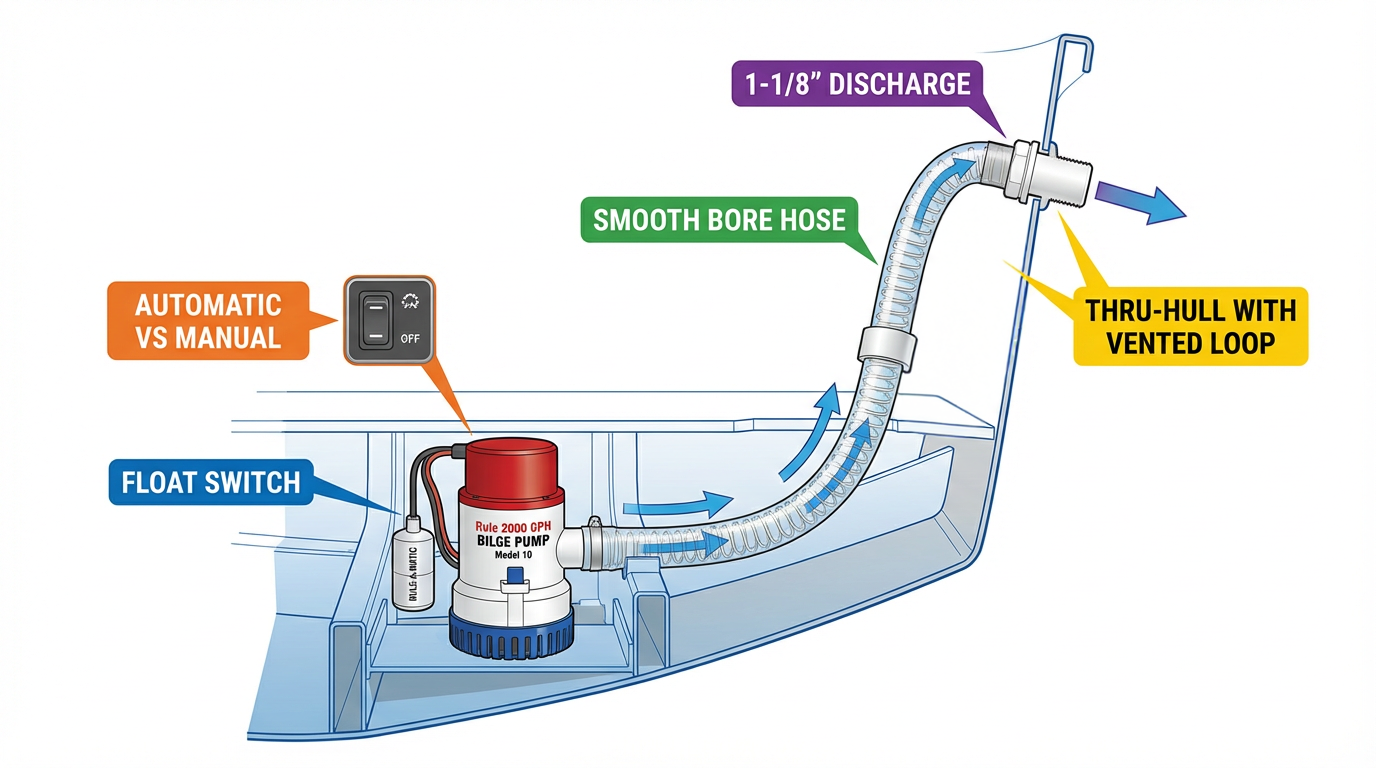

Whether you are replacing a burnt-out unit or upgrading for offshore safety, here is how to build a complete Bilge Evacuation System using the industry standard: Rule Pumps.

1. The Heart: Automatic vs. Manual Pumps

The first choice is the hardest. Do you want the pump to think for itself, or do you want to be the brain?

The "Set It and Forget It" Automatic

Automatic pumps, like the Rule Mate series, have internal sensors. They sense water and turn on automatically. Great for small skiffs or as a backup.

The "Pro Choice": Manual Pump + Float Switch

Most mechanics (and commercial captains) prefer a Manual Bilge Pump paired with a separate Float Switch. Why? Redundancy. If the switch fails, you can replace just the switch ($30) instead of the whole pump ($150). Plus, you can mount the switch higher or lower to control when it kicks in.

Shop All Manual & Automatic Bilge Pumps

2. The Heavy Hitter: Rule 2000 (Model 10)

For boats over 24 feet, the standard "500 GPH" toy pumps won't cut it. You need volume. The Rule 2000 (Model 10) is the gold standard for a reason.

- Capacity: Moves 2,000 gallons per hour (at zero head).

- Power: Efficient 12V motor drawing ~8.4 amps.

- The Critical Spec: It requires a 1-1/8" Discharge Hose. Do not try to force this into a smaller 3/4" hose—you will burn out the motor and lose 50% of your flow.

View the Rule 2000 GPH Pump Specs

3. The Veins: Smooth vs. Corrugated Hose

This is where flow goes to die. Cheap "corrugated" (ribbed) hose creates turbulence, slowing down the water. For a high-output pump like the Rule 2000, you need Smooth Bore Bilge Hose.

Pro Tip: Ensure your hose diameter matches your pump outlet exactly.

- 500-800 GPH Pumps: Use 3/4" Hose

- 1100-2000 GPH Pumps: Use 1-1/8" Hose

4. The Exit: Thru-Hulls & Loops

Getting water out of the bilge is one thing; keeping the ocean out is another. Your discharge hose must connect to a Thru-Hull Fitting well above the waterline.

If your thru-hull is near the waterline (common on sailboats), you must install a Vented Loop (Anti-Siphon Valve). This prevents ocean water from siphoning backwards into your bilge when the boat heels over.

Browse Stainless & Plastic Thru-Hulls

Summary: Your Shopping List

Don't just buy a pump. Build the system.

- The Pump: Rule 2000 (Non-Automatic)

- The Brain: Rule-A-Matic Float Switch

- The Plumbing: 1-1/8" Smooth Bore Hose + Stainless Hose Clamps